Material Characterization

Materials (metals, polymers, composites)

Whether it is for their qualification after manufacturing, the monitoring of possible aging or simply to constitute databases intended to feed calculation codes, the non-destructive evaluation of mechanical properties of materials represents both a scientific challenge and a real industrial need. Ultrasonic waves carry information required to achieve this objective because they apply mechanical and reversible loads to the propagation medium. Several types of waves may be used: bulk waves, guided waves, e.g. Lamb or Shear-Horizontal modes; but it is necessary to choose those which carry most information, which are the most suitable for the geometry of the medium, and also to properly choose the frequency domain according to the internal structure of the material. The experimental generation and detection of the selected waves then require dedicated equipment and specific processing of the measured signals. A numerical model faithfully simulating the experimental conditions is also necessary, as well as the resolution of the associated inverse problem, which will consist in the optimization of the material mechanical properties (input data in the propagation model) so that the calculated quantities match the measured ones (speeds, amplitudes, displacement fields, etc.). Various methods have been developed according to the type of materials, waves, surrounding medium (water, air), signal processing

Related Publications:

[B. Hosten et al., JASA vol 82, 1987 / S. Baudoin et al., Ultrasonics vol 34, 1996 / C. Aristegui et al., JASA vol 101, 1997 / M. Castaings et al., NDT&E vol 33, 2000 / B. Hosten et al., QNDE vol 20, 2001].

Evaluation of the cohesive or interfacial mechanical properties of adhesively bonded assemblies

Research studies focus on NDT ultrasonic methods applied to adhesively bonded assemblies. The aim is to non-destructively characterize mechanical properties which are representative of the interfacial adhesion or bondline cohesion. The considered assemblies are made of aluminum substrates and epoxy adhesive. Depending on the geometry of the studied assemblies, two methods are used to obtain quantitative information on the adhesion level.

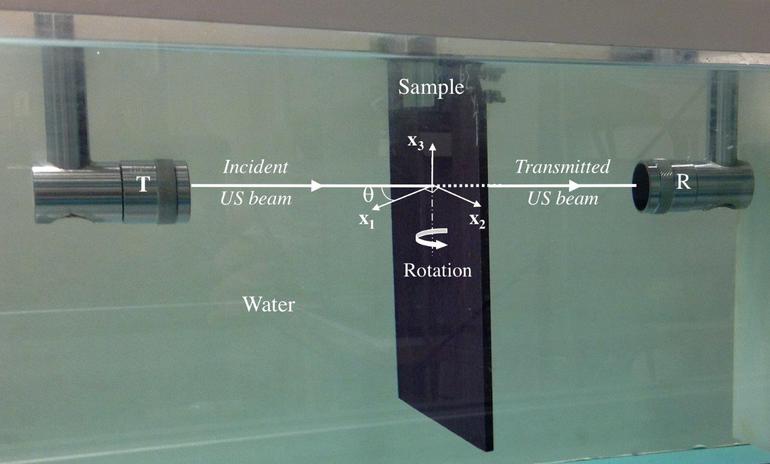

A first method is suitable for three-layered plate-like samples. It consists in analyzing the transmission of bulk ultrasonic plane waves through the assembly immersed in water. It has been shown that an inappropriate surface treatment of the substrates cause an apparent anisotropy of the measured elastic moduli of the joint. This anisotropy was quantified using two parameters whose values can reveal the quality of the interphases.

Stiffnesses kL and kT of the interfaces can be estimated. It was shown that their values are higher when the adhesion is nominal, and are strongly decreased when the adhesion is degraded. Measured shear strength for lap-joint samples bonded under the same conditions, decreased as the adhesion is supposed to be degraded, showing agreeing changes between mechanical tests and ultrasonic measurements.

The second ultrasonic method is more suitable for large lap joint samples. It is based on the Lamb or Shear Horizontal wave transmission coefficients measured from one substrate to the other, across the overlap zone. Those transmission coefficients are obtained thanks to home-made capacitive air coupled transducers (or to EMATs) which allow contactless generation and detection of Lamb waves (or SH waves) with a good signal to noise ratio.

Experimental measurements of the Lamb wave transmission coefficients were performed on two samples. One of them has interphases with nominal adhesion and the other has degraded interphases. The comparison between the measured results and numerical simulations obtained for different modes was used to determine the values of the interfacial stiffnesses for each sample. Again, it was observed that poor adhesion leads to low values of the interfacial stiffnesses of the interphases, that can be quantified using guided ultrasonic waves. The obtained values of the stiffnesses were in good agreement with previous ones from the first ultrasonic method.

Related publications:

[Siryabe et al, Ultrasonics 79, 2016]